Pats String Jig

- Details

- Category: Guidance

- Published: Wednesday, 09 December 2020 02:43

- Written by Super User

- Hits: 3101

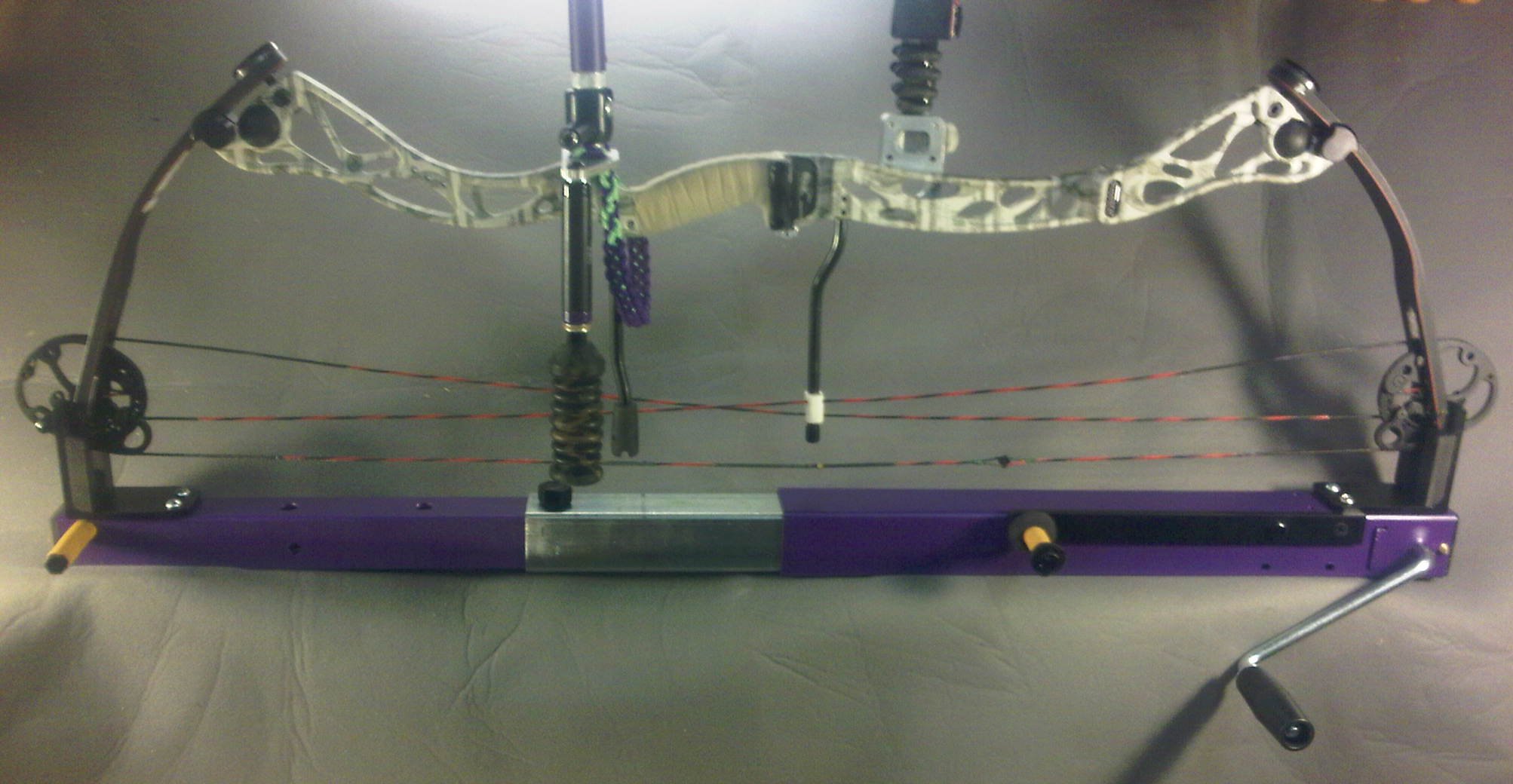

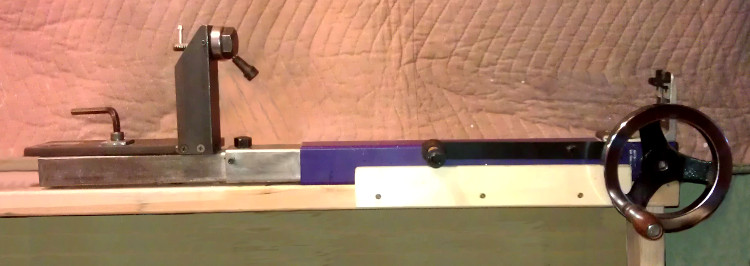

My String Jig:

although not for sale, I'm willing to show my string jig setup for your use. Feel free to copy any of the parts you see and make your own. The benefits of my jig are the ability to stretch the string without removing the string from the jig. it's also a lot easier to make micro adjustments to the length and remove tension on the string when building. Less tension makes it easier to rotate the posts and more tension is helpful when apply end serving and other build tasks.

Properties of a good string jig are solid construction and adjust ability. Most incorporate a separate tensioning mechanism so you can twist and stretch the string to at least 300# before you apply your servings. If you are not interested or lack the facilities to build your own "Little Jon" aka Deezlin makes a nice unit as well as Munch on archery talk.

Here is how I made mine and why:

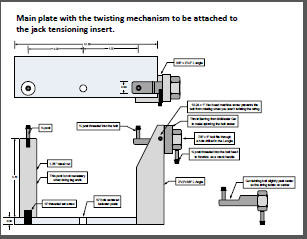

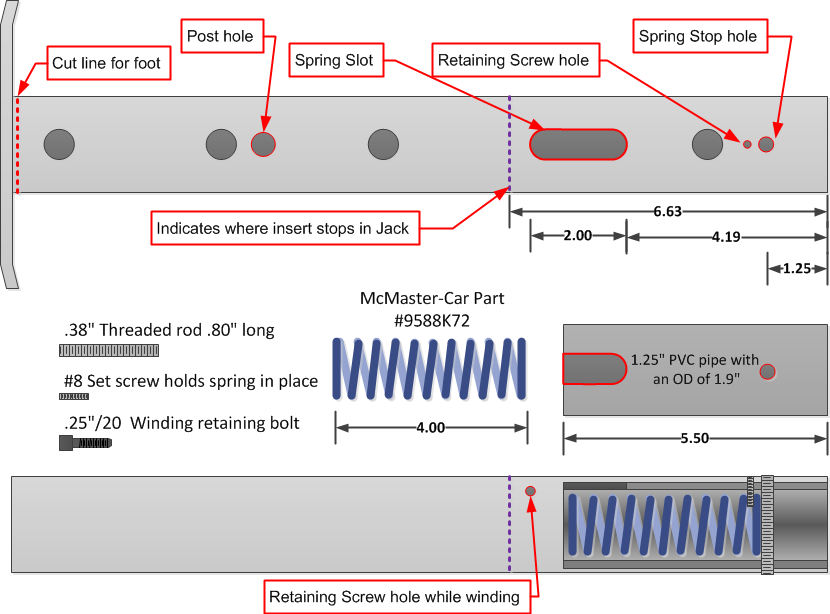

Oh and here are the drawings that could help potential builders

I started with a Harbor Freight jack. from there I added some uni-strut. I converted the lower part of the jack into a tensioning device complete with compression spring. It is inserted into the jack and held in place with the post. As you apply tension to the string with the crank the spring compresses . Based on the amount of compression you can determine the amount of weight being applied to the string. I bolted the jack and unit-strut in place on the bench and got to work. for more info or to add a comment about the jig you can check it out on Archery Talk at this link: http://www.archerytalk.com/vb/showthread.php?t=1374668

Click on the Jack to see the harbor freight listing.

I've included a drawing of the tensioning insert, click on the image to enlarge it. Also included are some photos of the completed tensioner complete with the posts.

On one of the posts I incorporated a string twister. With this setup I can complete the full string without ever removing it from the Jig.

I had my brother mill me out some heavier duty posts and plates. The less flex you have in your jig the better. As you wrap thread around the posts the they add additional pressure to the jig. If it flexes it will cause your first wraps to become loose. inconsistent thread tension causes all sorts of problems and should be avoided.

By the way, with a few other attachments the jack also functions as a bow press and a draw board.