Get the Wobble Out

- Details

- Category: Guidance

- Published: Wednesday, 09 December 2020 02:46

- Written by Super User

- Hits: 2173

One of the issues end users have reported is excessive side to side wobble. We'll give you some suggestions on how to minimize this but it may still take some experimenting on your part to see what works best for you. The number one thing to understand is that you want the spinner as close to perpendicular to the string as you can get it. Below are some images and tips to help you get there:

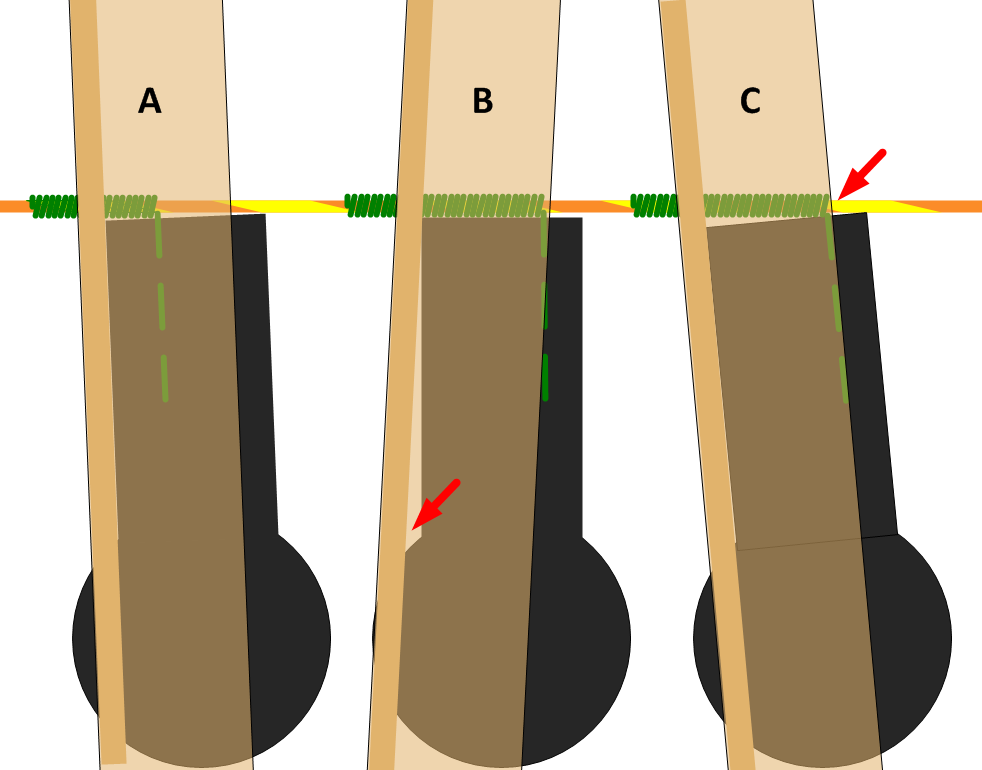

first lets look at what could be wrong.

Image ( A ) shows the bobbin with the pay out hole on the inside with loose serving tension this causes the bobbin to sit at an angle to the string.

Image ( B ) Shows the bobbin with the pay out hole to the outside of the Spinner with moderate tension but the bobbin is not completely pushed into the NW Spinner.

Image ( C ) shows the pay out hole on the outside with enough tension that it pulls the bobbin in at an angle, this is the worst setup because it can cause inconsistent wrapping.

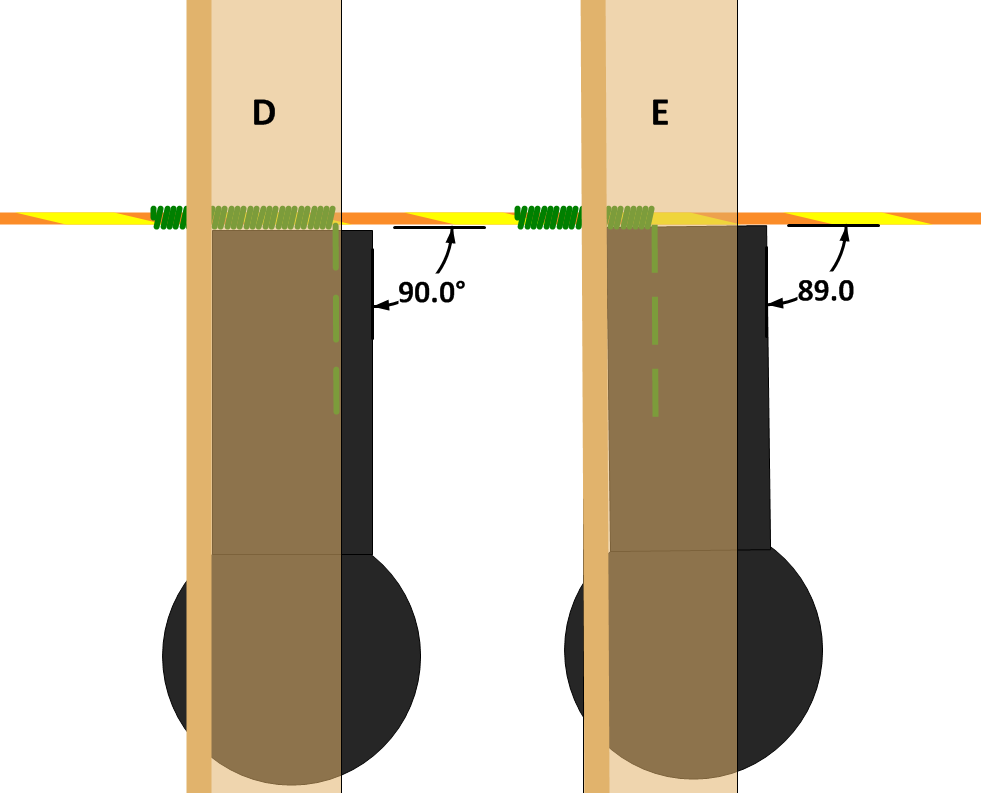

Below are two scenarios that have worked for us.

Image ( D ) Shows the long portion of the bobbin flush against the wound serving and the pay out hole to the outside of the Spinner. This is achieved with moderate serving tension and can be applied with nearly no wobble.

Image ( F ) Shows the bobbin with the pay out hole to the inside of the Spinner with significant tension. The higher tension actually mashes the bobbin tight enough that you get a nearly 90 degree angle well close enough that wobble is insignificant.

We use Method ( D ) when installing large diameter center serving adjusting the tension as tight as possible without causing the bobbin to tip over. However on the end servings where we use smaller diameter thread and we want a really tight wrap we use ( E ) this does introduce a slight wobble but the end results are tighter and less prone to movement.

We hope hope this helps you get the very best out of your NW Spinner.